Smart Textiles Design Lab Blog at The Swedish School of Textiles

Soft Sensing Structures

The basic principle to construct an electric switch is to have two conductive contacts that do not touch when the switch is idle, and touch when it is activated (or the other way around). A sensor can use two contacts but produces a range of values instead of just changing from one state to another. The contact in the switch and the value range in a sensor are measured by the change in voltage by a micro controller. With a digital switch, the difference in voltage is usually between minimum and maximum. With a sensor, the range ideally varies from minimum to maximum with all measurable steps in between, but it might also be restricted to a certain voltage range, especially for custom-made sensors.

These working modes for sensors and switches can be reproduced in textile materials. The contacts of a textile switch can e.g. consist of two patches of conductive fabric that touch when the cloth is folded. Textile materials that vary their resistivity when they are squeezed or stretched produce the voltage range of an electric sensor. Again, the switch or sensor might entirely rely on the changing properties of a single textile material, or it might be a result from a textile pattern that is based on the basic switch construction principle. I constructed two pressure switches using knitting and weaving. Both are based on the textile structure, and both can be produced on industrial machines.

The knit pressure sensor matrix acts as a switch or sensor, depending on the distribution of conductive threads in the pattern. With knitting, one can create three-dimensional structures on the surface of the knit using so-called hang-up stitches. These are stitches that remain on the needles while only the surrounding stitches are knit. Using two needle beds, this technique is used to produce a relief-like structure, where parts of the knit are slightly elevated from the surface.

The stitches lie on top of each other in two layers that are slightly separated. When one applies pressure to the knit, the layers bend down and touch. I developed this particular sensor together with Pauline Vierne, a fellow researcher from University of Arts Berlin.

On a hand-knitting machine, stitches can be hung up manually after they have been knitted down from the needle bed. Another way to make a simple relief is to use a double bed setup and to combine plain knit and rib stitches. Whenever the needles on one bed are left idle, and the needles on the other bed are knit, they will create a small bulge on the surface structure.

The manual lifting of stitches that are knit down from the needle beds is obviously not possible on an industrial knitting machine. However the double bed relief pattern can be implemented without further modifications.

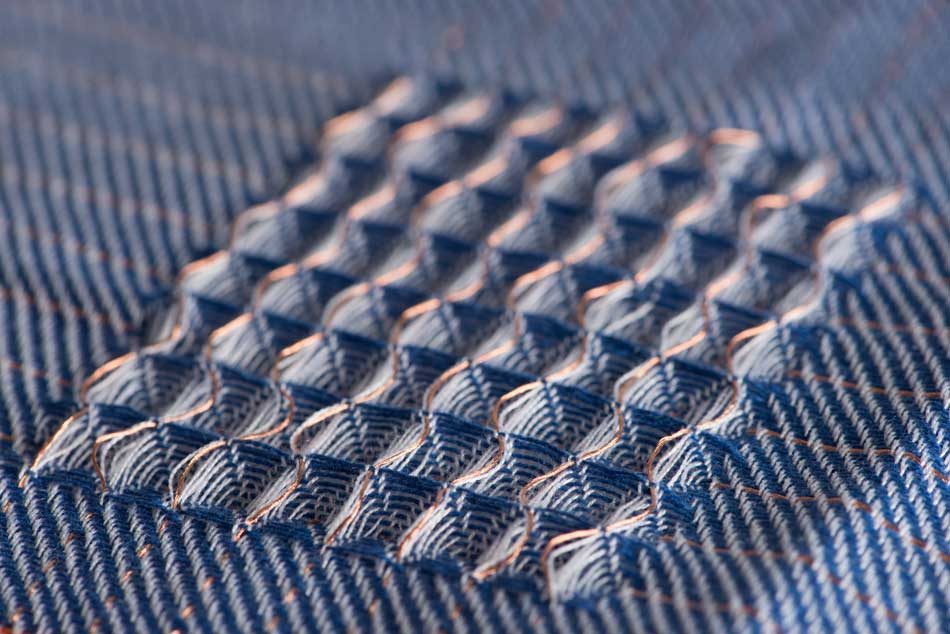

Similar to knitting, weaving as a textile construction technique offers various ways to create custom sensors and switches only through the careful distribution of conductive threads within the material structure. What makes weaving particularly versatile and attractive for textile sensing structures are the possibilities to create multiple separated or interlocked layers and to combine these with three-dimensional or relief-weaving patterns such as waffle weave.

The waffle pattern is a basic weaving pattern that makes the threads pile up to form a three-dimensional textile structure. This effect comes from a particular distribution of binding points and floats that elevates and lowers the threads in the warp and weft direction in a particular way. As a result, a square-like three-dimensional surface forms. The larger the repeat is, the deeper the structure becomes.

In a waffle weave, the threads that have the least binding points between warp and weft are the ones that represent the highest and deepest edges of the structure. In these areas, the warp and weft threads that are not bound float on top of each other. They will not touch if the fabric is not pressed because the structure is naturally elastic and push the floating threads apart. This effect can be used to create a waffle weave where conductive threads are inserted exactly into the warp and weft where the weave structure itself will hold them apart. If one then presses the textile, the two threads will touch.

Katharina Bredies, postdoctoral researcher