Smart Textiles Design Lab Blog at The Swedish School of Textiles

Textile Muscles

This research is part of the project „Design, Textiles and Sustainable Development“, a joint activity of the universities of Borås and Skövde, funded by Västragötalandsregionen.

Thinking about a common research theme that would equally contribute to the fields of robotics, materials research and design research, the postdoctoral researchers together came up with the idea to work on soft robotics. The challenging aspect of this work was that the construction of the textile muscles and the development of the robot morphology had to go hand in hand.

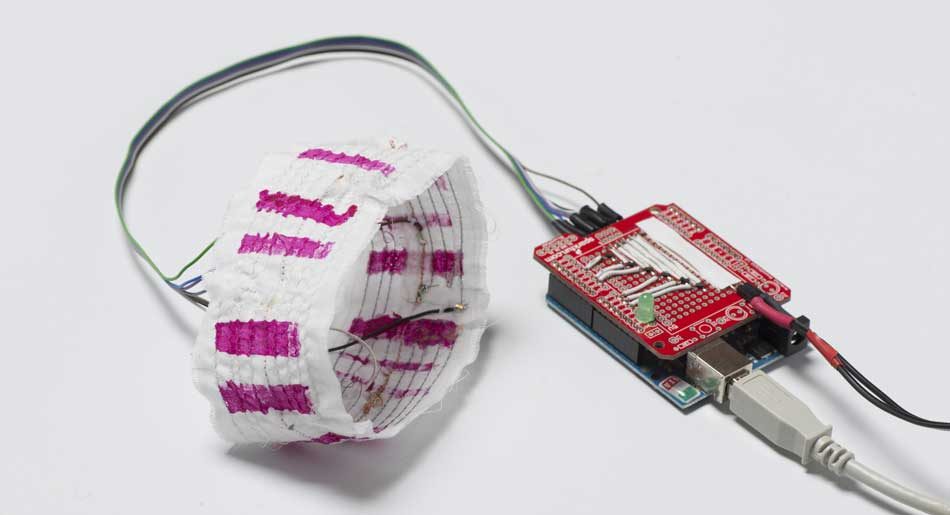

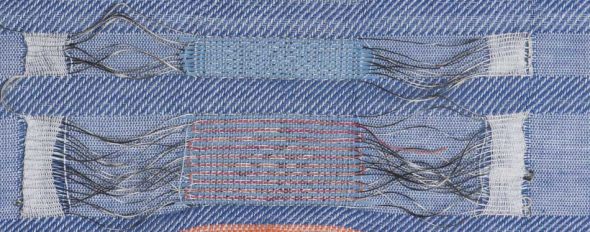

My part was to investigate the possibilities to build textile muscles, i.e. structures that could expand and contract with actuation from a micro controller. For the actuation, I experimented with shape memory alloy (SMA) as well as polymer coils, which both react to heat. I tried out knitting and weaving as construction techniques for the muscles, and I used readymade SMA materials as well as those that I had to anneal into shape myself. As for the polymer coils, I produced coils from conductive and non-conductive polymers in different thicknesses and length and wove them in with heating yarns and conductive connections. I also added elastic materials as a counter-force to the SMA and coils, so that the muscle could actually go both ways.

Many aspects of our common research were unexplored, from the performance of shape memory alloys and contracting polymer coils to the possible shapes of a soft robot. Also, the application of kinetic textiles is not yet fully established, since soft robotics is a rather young field altogether. Therefore it was a real challenge to make the textile move as intended. However, for me it was important to use the textile technique and exploit their possibilities rather than use an additive approach. I was not primarily interested in an ideal performance – although that would have been nice! – than to investigate the combination of textile techniques with shape-changing materials.

Therefore I tried out a combination of textile structures and materials that would expand the material (such as straight annealed SMA or monofilament) and those that would contract the material (such as waffle weave, polymer coils or elastane). Part of the development involved dealing with the heating yarns and a proper electrical connection to heat up the patches to the necessary temperature to make the contract or expand. The result is an alternative approach to constructing robots based on the logic of textile construction techniques.

Katharina Bredies, postdoctoral researcher